Engineering Class Sprockets

engineering-class-sprockets-1

Start with High-Quality Materials

U.S. Tsubaki sprockets for Engineering Class Chain are made with quality material—usually carbon steel. Heat-treated carbon steel provides long wear life, resists abrasion, and withstands heavy shock loads. We can also manufacture sprockets using special materials to meet your specific needs. For example, we can make sprockets from alloy steel, stainless steel, or bronze. The result is always the same: U.S. Tsubaki sprockets are designed to maximize the life of your chain and to keep your operation running smoothly.

Flame Cut for Long Wear

U.S. Tsubaki sprockets are flame machined, not torched. This special manufacturing operation ensures hardened teeth that stand up to rigorous applications. And we build the same quality into every manufacturing step. We use state-of-the-art computer-driven machinery to precision manufacture heavy- duty sprockets that consistently provide the highest standard of performance.

Get Added Locking Power FREE!

Two set screws are standard on every U.S. Tsubaki Engineering Class Sprocket. No additional cost. No additional waiting time. That means on-line locking power where you need it most. Two set screws hold sprockets in place well and that means less wear and tear on costly shafting.

Select the Sprocket You Need

U.S. Tsubaki offers a full line of Engineering Class Sprockets. In addition to providing Engineering Class Sprockets for every U.S. Tsubaki chain, our sprockets can be used with chains made by many other manufacturers. Check the Sprocket Cross-Reference Chart in Section D of this catalog. If you have any questions, please contact U.S. Tsubaki.

/Asset/engineering-class-sprockets-new-img.png

/Asset/engineering-class-sprockets-new-img.png

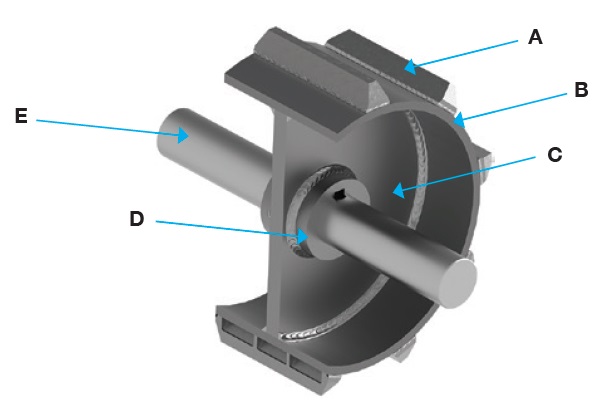

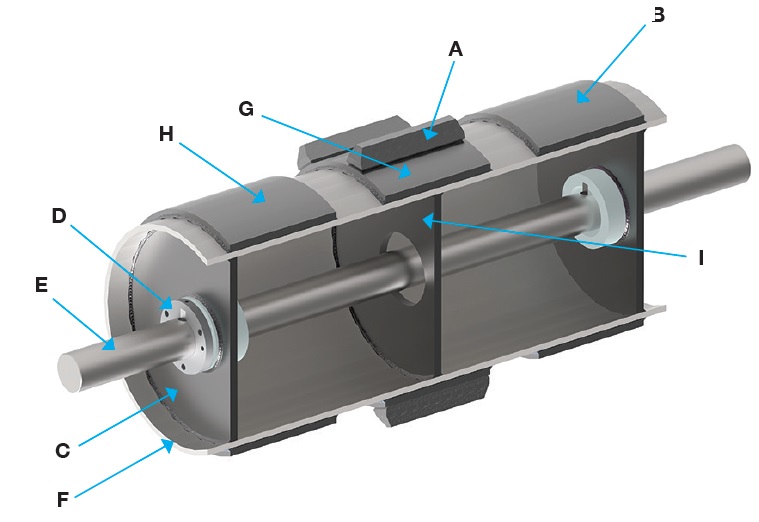

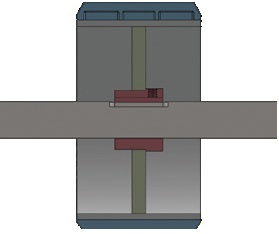

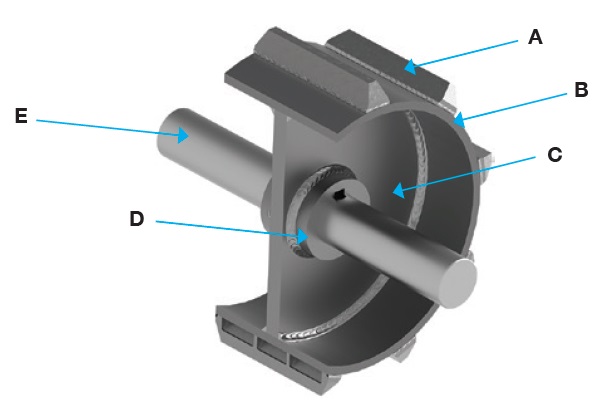

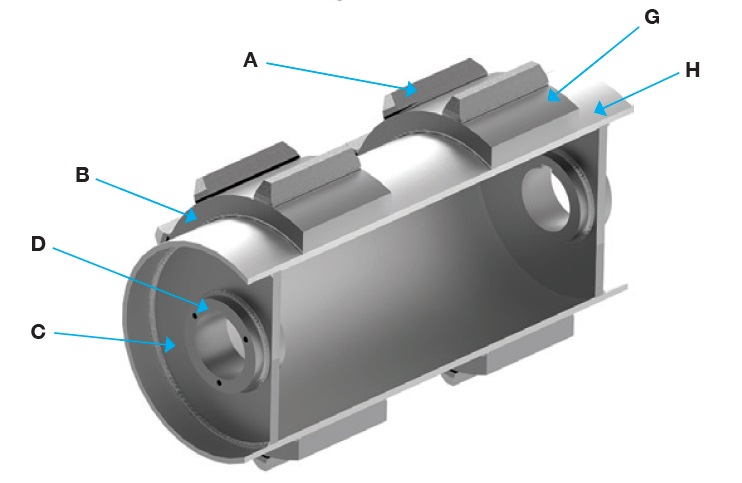

SINGLE DRUM SPROCKET

The Can is the main structural member of the drum assembly. Teeth are typically welded to the Can to provide positive traction, but traction wheel (toothless) style designs are also available.

A - Teeth

B - Can

C - Hub Plate

D - Hub

E - Shaft

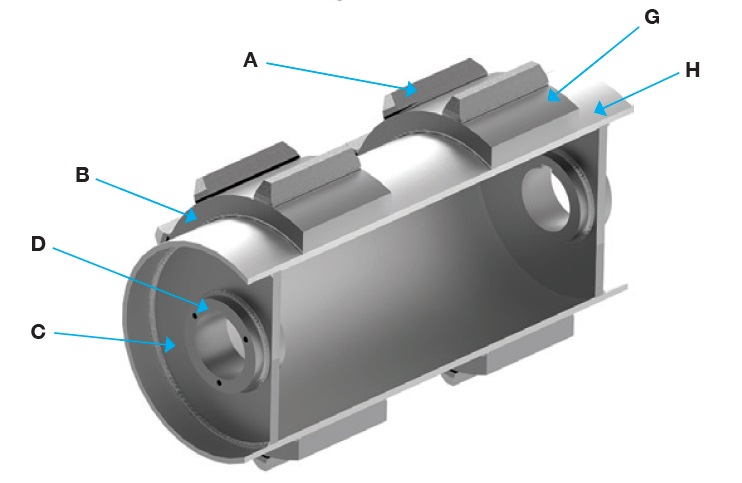

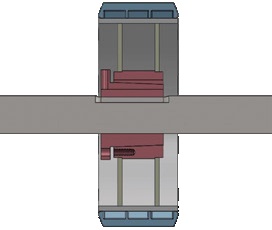

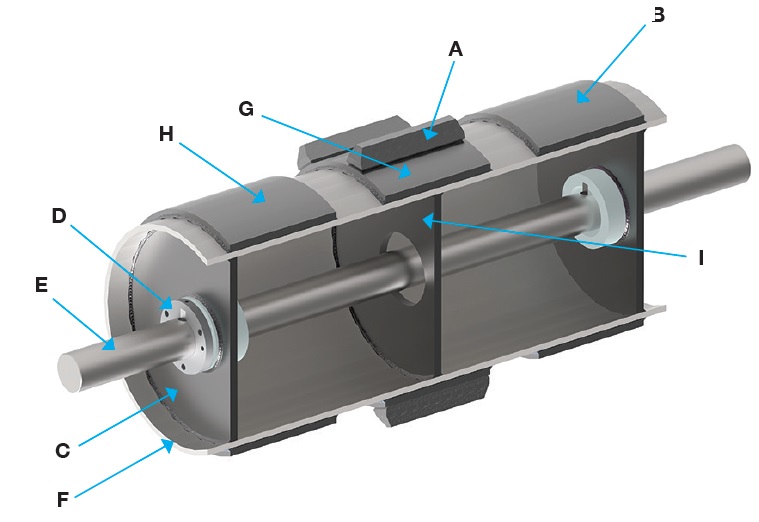

DOUBLE DRUM SPROCKET

Multi-strand drums are typically supplied with a Shroud. This allows for added strength and structural rigidity. Multi-strand drums without a Shroud are available upon request.

A - Teeth

B - Can

C - Hub Plate

D - Hub

G - Sprocket

H - Shroud

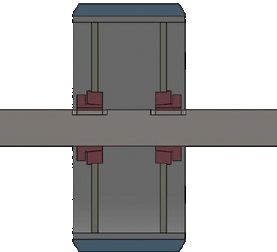

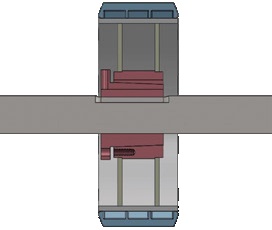

TRIPLE STRAND, COMBINATION SPROCKET & TRACTION WHEEL

Support Plates are utilized to provide additional structural rigidity and strength on triple strand drums and larger.

A - Teeth

B - Can

C - Hub Plate

D - Hub

E - Shaft

F - Shroud

G - Sprocket

H - Traction Wheel

I - Support Plate

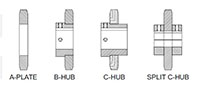

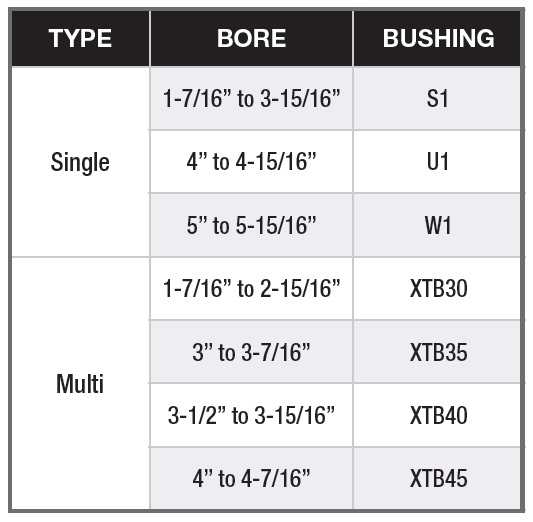

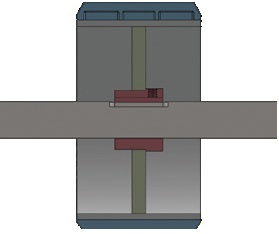

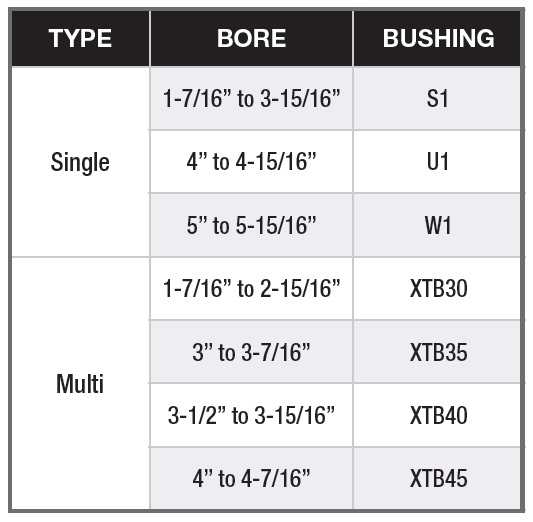

HUB STYLES

Style 1 for bores up to 3-15/16”.

Style 2 with double hub plates are required for bores greater than 4”. Split Taper bushings are standard for single style hubs.

Style 3 For ease of installation XTB type bushings are suggested for double hub construction.

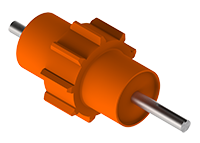

/Asset/Full-Face-Drum-Sprocket_Orange-110.png

/Asset/Full-Face-Drum-Sprocket_Orange-110.png

Engineering Class Sprockets

Chains and sprockets must work together, so buying them from the same source makes sense. When chains and sprockets articulate correctly, the life of the chain is extended. That means long-term savings and real value for your application.Start with High-Quality Materials

U.S. Tsubaki sprockets for Engineering Class Chain are made with quality material—usually carbon steel. Heat-treated carbon steel provides long wear life, resists abrasion, and withstands heavy shock loads. We can also manufacture sprockets using special materials to meet your specific needs. For example, we can make sprockets from alloy steel, stainless steel, or bronze. The result is always the same: U.S. Tsubaki sprockets are designed to maximize the life of your chain and to keep your operation running smoothly.

Flame Cut for Long Wear

U.S. Tsubaki sprockets are flame machined, not torched. This special manufacturing operation ensures hardened teeth that stand up to rigorous applications. And we build the same quality into every manufacturing step. We use state-of-the-art computer-driven machinery to precision manufacture heavy- duty sprockets that consistently provide the highest standard of performance.

Get Added Locking Power FREE!

Two set screws are standard on every U.S. Tsubaki Engineering Class Sprocket. No additional cost. No additional waiting time. That means on-line locking power where you need it most. Two set screws hold sprockets in place well and that means less wear and tear on costly shafting.

Select the Sprocket You Need

U.S. Tsubaki offers a full line of Engineering Class Sprockets. In addition to providing Engineering Class Sprockets for every U.S. Tsubaki chain, our sprockets can be used with chains made by many other manufacturers. Check the Sprocket Cross-Reference Chart in Section D of this catalog. If you have any questions, please contact U.S. Tsubaki.

/Asset/engineering-class-sprockets-new-img.png

/Asset/engineering-class-sprockets-new-img.png

Sprocket and Traction Wheel Types

Leverage the following data sheets to accurately document your sprocket for a quotation… /Asset/Sprocket-Quotation-Request---Standard-Sprockets---Traction-Wheels.jpg

Drum Style Sprockets

Leverage the following data sheets to accurately document your sprocket for a quotation…SINGLE DRUM SPROCKET

The Can is the main structural member of the drum assembly. Teeth are typically welded to the Can to provide positive traction, but traction wheel (toothless) style designs are also available.

A - Teeth

B - Can

C - Hub Plate

D - Hub

E - Shaft

DOUBLE DRUM SPROCKET

Multi-strand drums are typically supplied with a Shroud. This allows for added strength and structural rigidity. Multi-strand drums without a Shroud are available upon request.

A - Teeth

B - Can

C - Hub Plate

D - Hub

G - Sprocket

H - Shroud

TRIPLE STRAND, COMBINATION SPROCKET & TRACTION WHEEL

Support Plates are utilized to provide additional structural rigidity and strength on triple strand drums and larger.

A - Teeth

B - Can

C - Hub Plate

D - Hub

E - Shaft

F - Shroud

G - Sprocket

H - Traction Wheel

I - Support Plate

HUB STYLES

Style 1 for bores up to 3-15/16”.

Style 2 with double hub plates are required for bores greater than 4”. Split Taper bushings are standard for single style hubs.

Style 3 For ease of installation XTB type bushings are suggested for double hub construction.

/Asset/Full-Face-Drum-Sprocket_Orange-110.png

/Asset/Full-Face-Drum-Sprocket_Orange-110.png